This week we got introduced to laser cutter and cutting plotter.

First we needed do design vector image for making stickers.

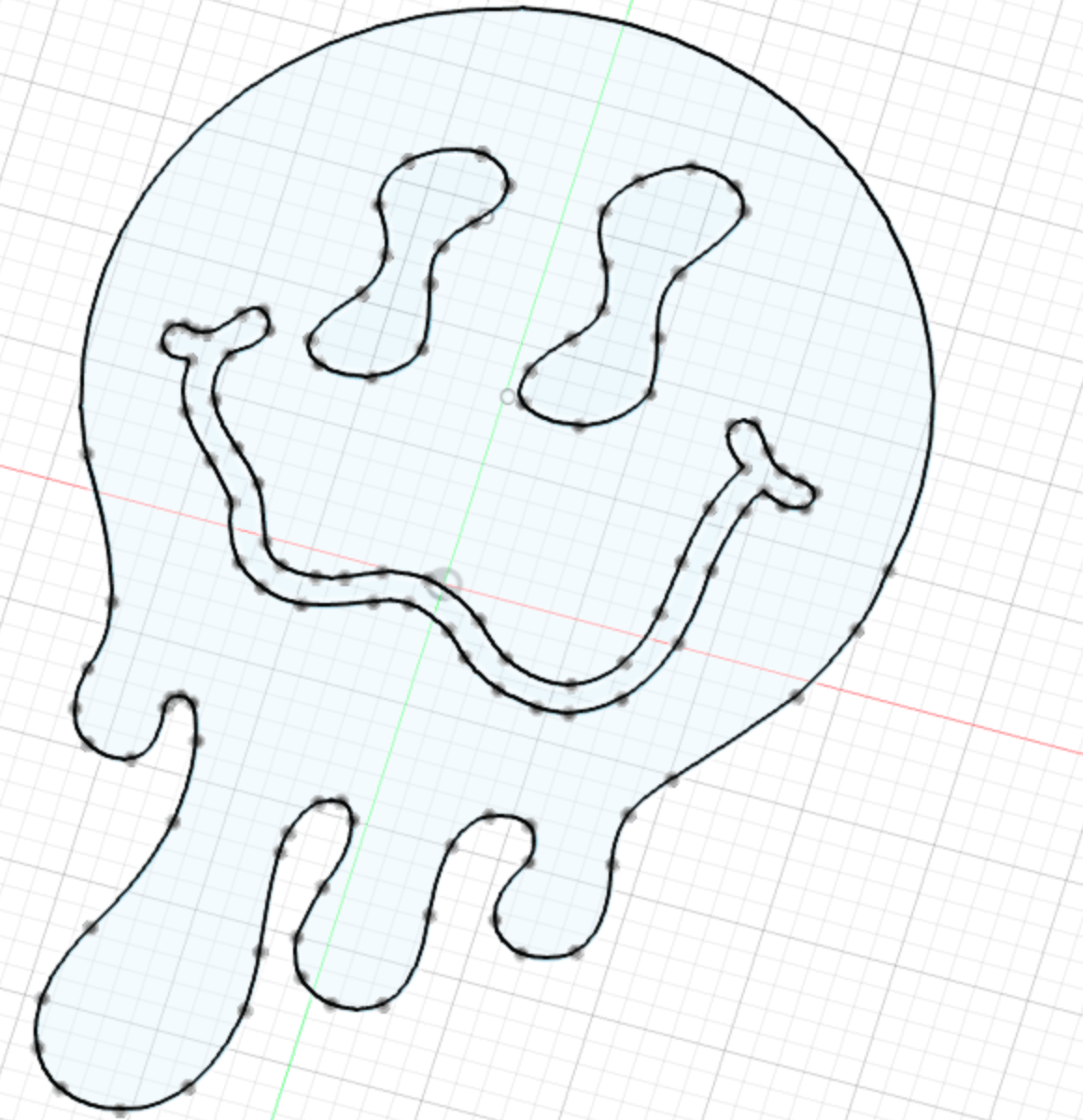

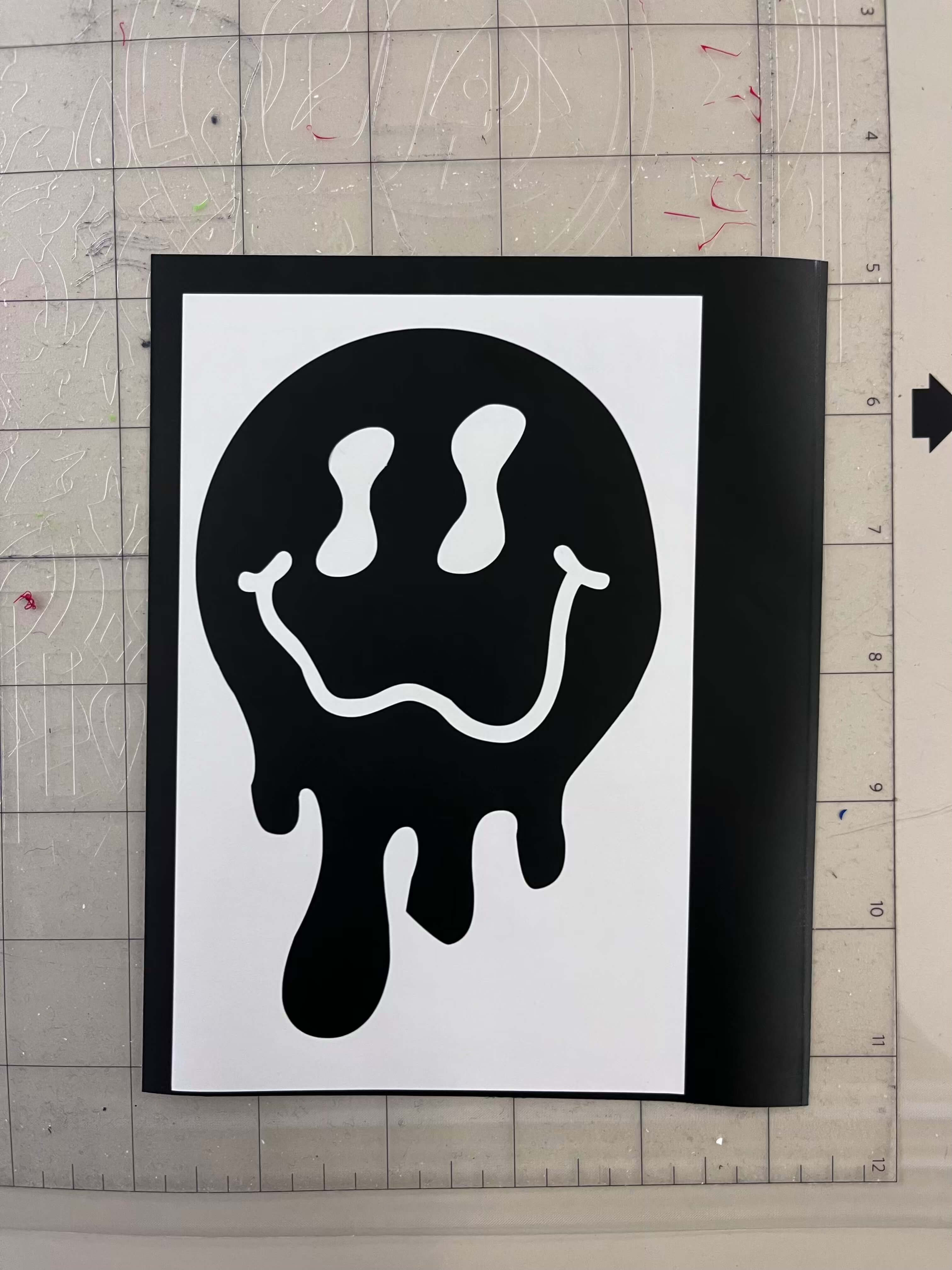

I made this drippy smiley face.

I copied an image off internet and imported it to Fusion360 as canvas.

Then i traced it with lines.

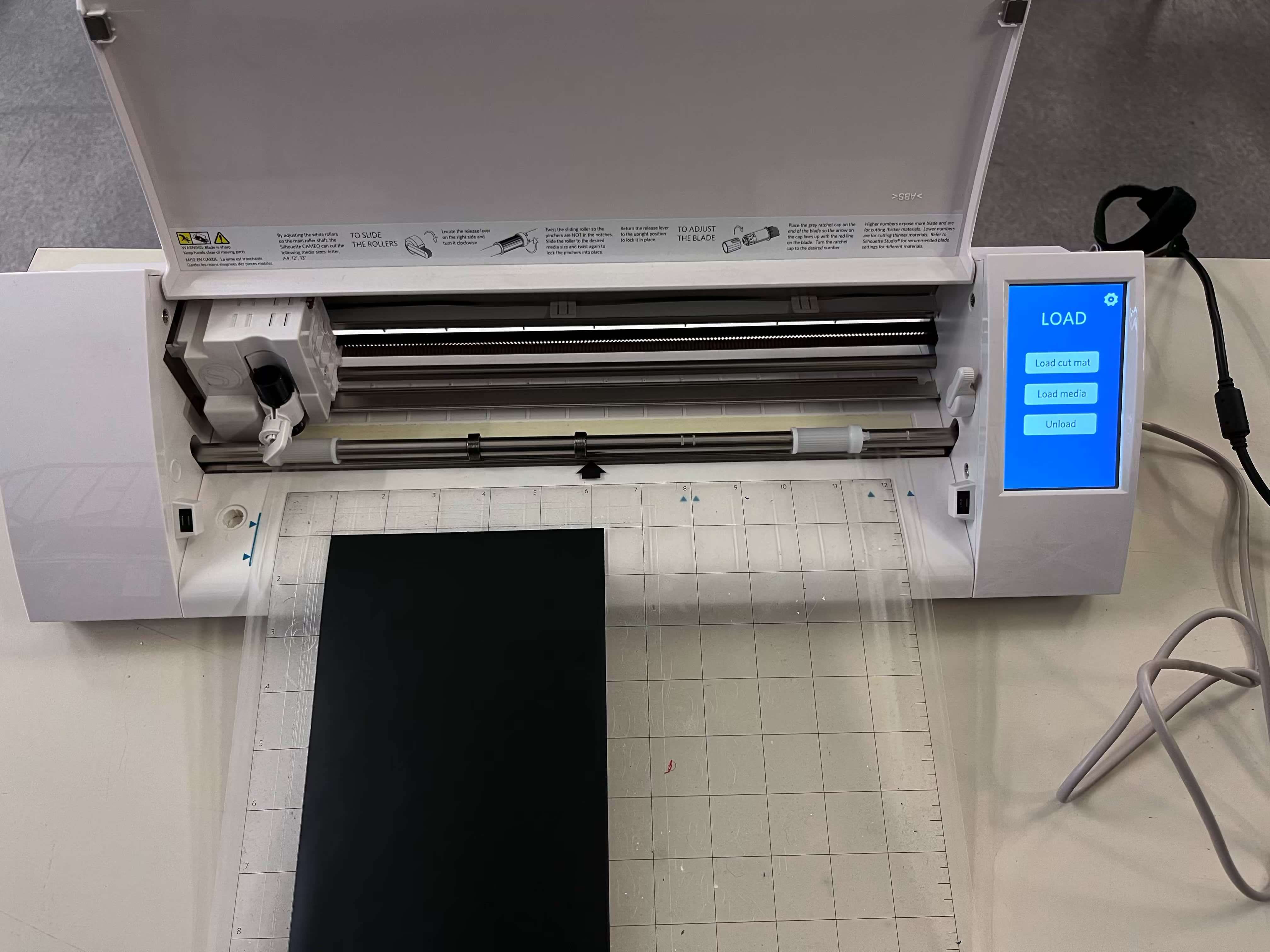

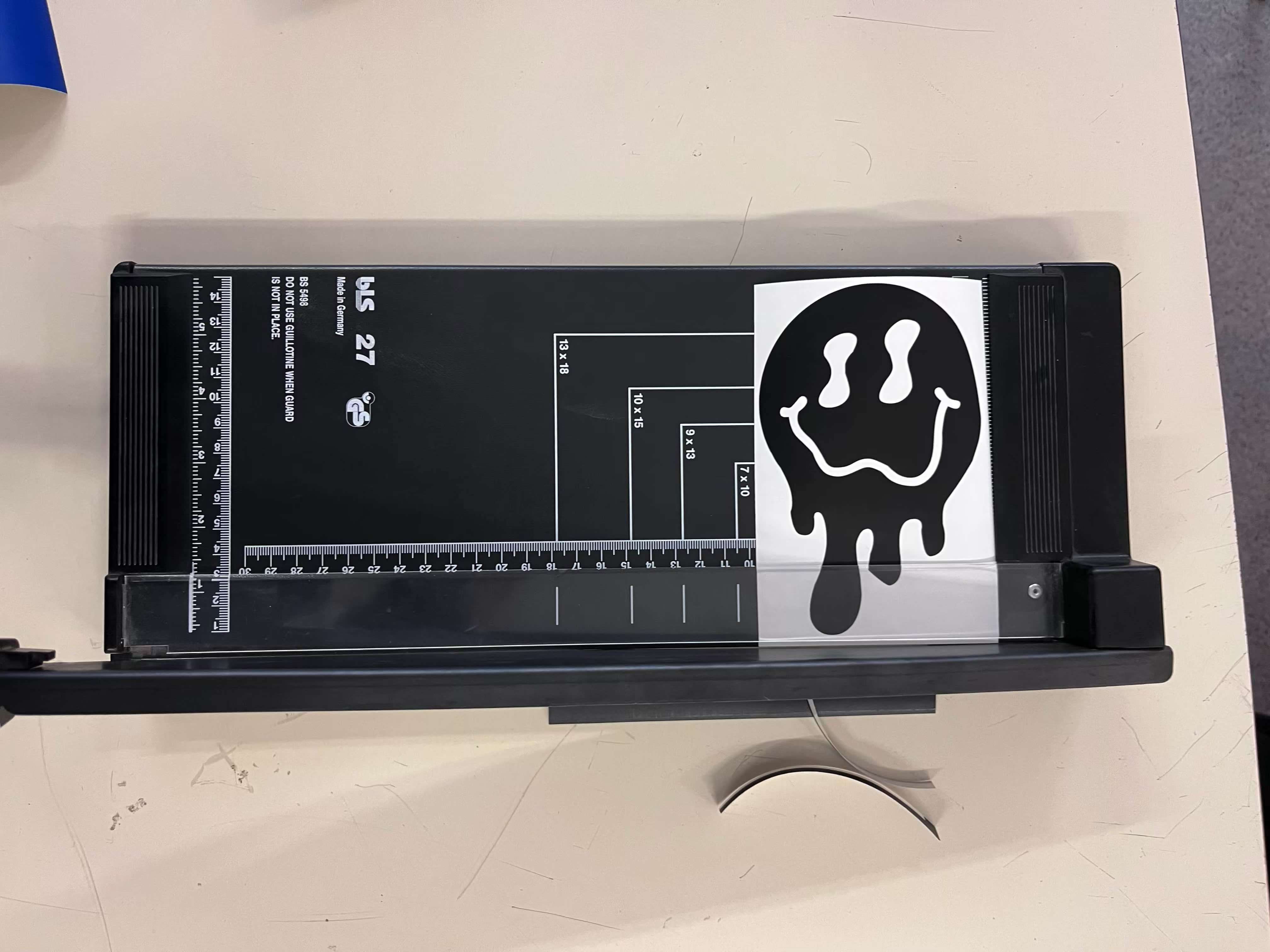

After that the image is exported as dxf file and loaded in special software

used for cutting plotters. We used Silhouette Studio.

Than correct material needs to be selected and than loaded inside the cutting plotter.

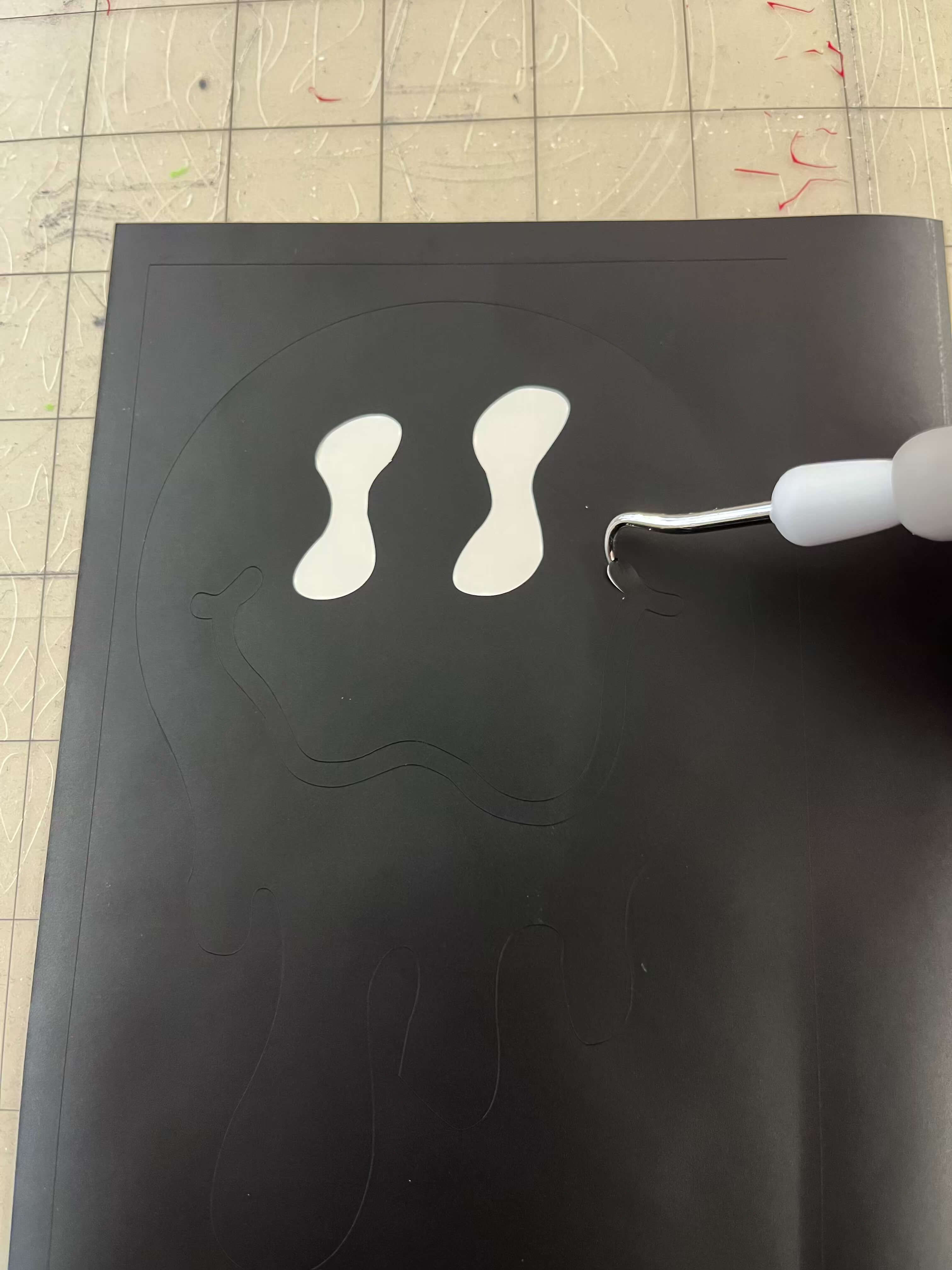

After the plotter is done cutting, excess material needs to be removed.

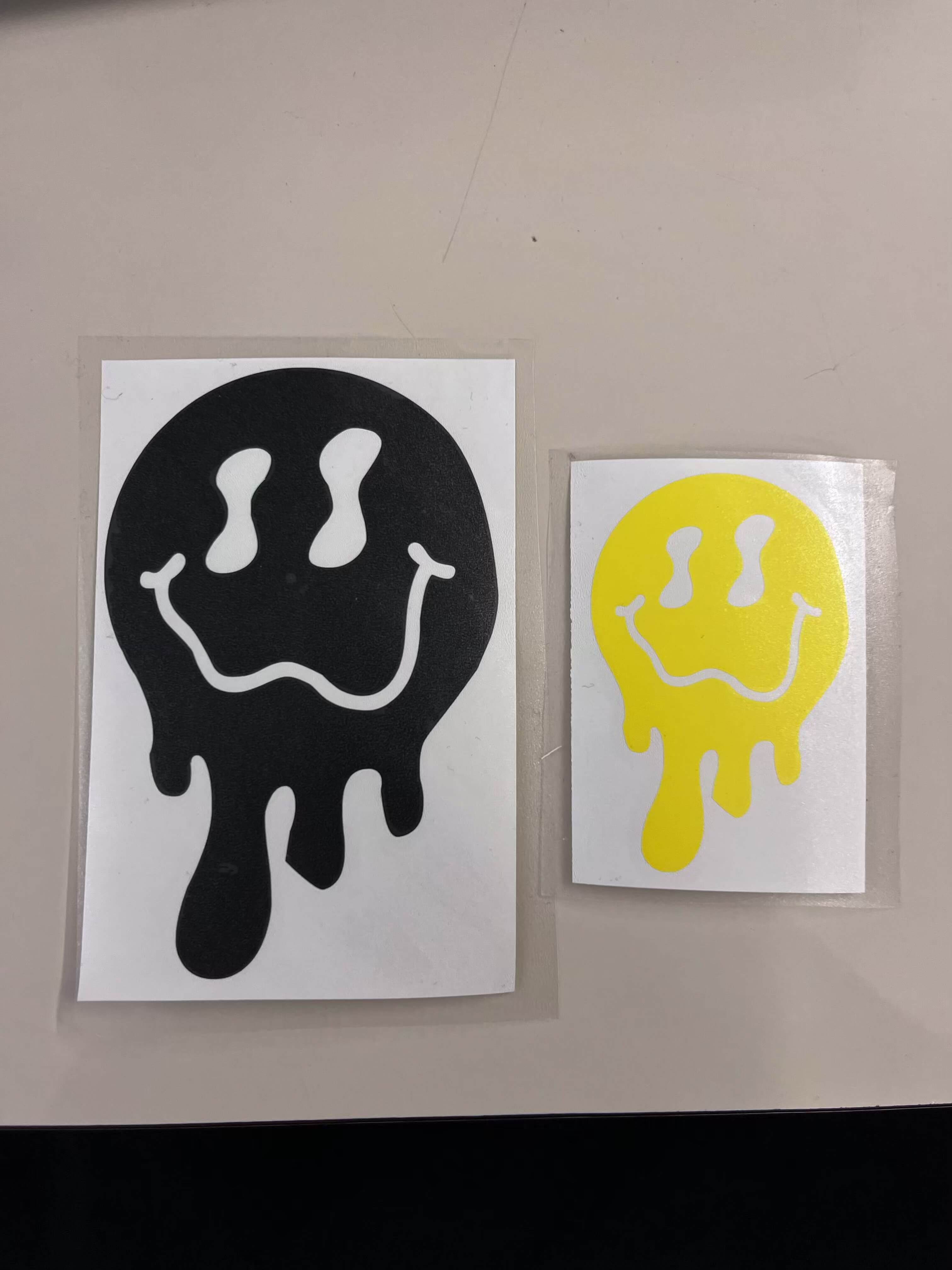

Here is how it looked after removing all excess material.

Now there are are only two steps left to do. Cut the sticker to smaller size and adding protective foil. Here is how the results looked.

After finishing our stickers we moved to laser cutting.

Here are some designs i prepared for laser cutting. I made more variations,

with varying slit depths and other small tweaks.

It was important to make at least the slit width parametric, because it takes a lot tweaking to get the perfect cut. Remodeling the models with each little tweak would be exhausting and time consuming.

Here is how my cuts turned out.